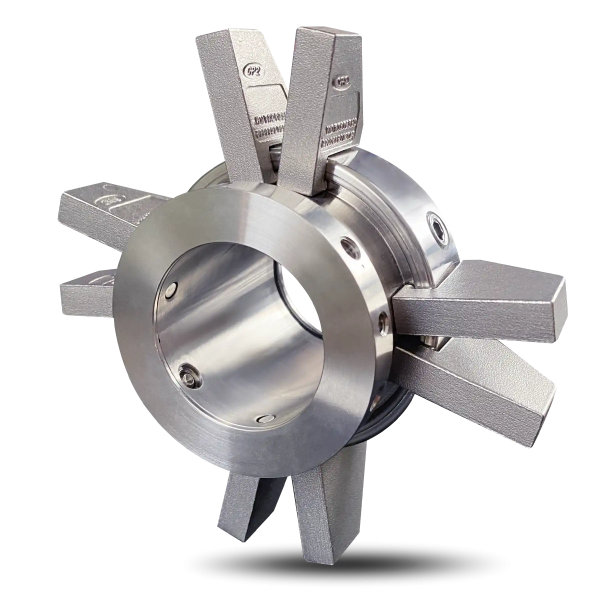

1510 & 1510L General Duty Cartridge Seals

Simple Installation and Increased Reliability Plant-wide in General Duty Applications Maximize maintenance efficiency and increase plant productivity with the 1510 Single Cartridge Seal. Designed to fit process equipment plant-wide by incorporating Chesterton T.A.B.S. (Tapered Adjustable Bolting System) the compact profile makes seal installation easy.

Reliability through temperature variations and intermittent operations is ensured with the use of monolithic seal faces and true non-fretting construction. Impeller adjustments after seal fitment are accommodated with the unique resettable centering strap, even when adjustment is required between routine maintenance. Incorporating Chesterton’s 5 key features of good mechanical seal design, the Chesterton 1510 sets the new standard for general duty cartridge seals.

The 1510L features a single screw lock ring that uniformly claps the seal to the shaft and simplifies removal in fluids that tend to set or clog around the seal.

Specifications

| Elastomers | FKM, EPDM, FEPM, FFKM |

| Faces | CB, SSC, TC |

| Metals | 316SS |

| Pressure Limit | 711 mm (28") Hg Vacuum to 20 bar g (300 psig) |

| Shaft Speed | 25 m/s (5000 fpm) |

| Sizes | 25 mm to 120 mm (1.00" to 4.75") |

| Springs | Alloy C-276 |

| Temperature Limit | -55°C – 300°C (-67°F – 570°F) |

Options & Accessories

SpiralTrac Environmental Controller

The SpiralTrac™ Environmental Controller is an exclusive, patented throat bushing specially engineered to transform and control the internal stuffing box environment in rotating process equipme...

More Info

More Info