Sanitary Progressing Cavity Pumps

Sanitary Pumps

Designed to meet FDA requirements in a variety of food and chemical applications. Low-shear, non-pulsating Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress.AugMentor™

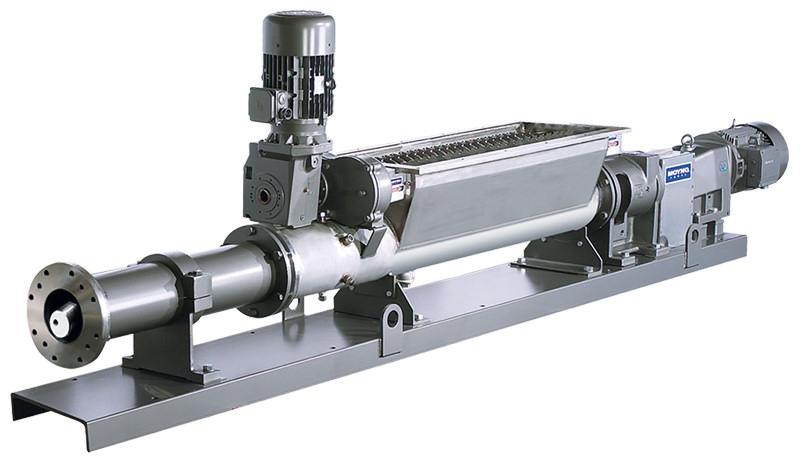

The AugMentor® Pump Stuffer handles high-viscosity materials otherwise unpumpable by conventional means. Materials in excess of 1,000,000 cps, such as cold processed meats and bakery dough, are easily fed by the AugMentor's slow-speed, bottom-drive auger.Chopper Hopper™

Moyno™ has created a food products processor that combines solids reduction and transfer pumping into one efficient unit. The patented Chopper Hopper™ is a unique and aggressive solids reduction pumping system that reduces whole produce - papayas, pineapples, pumpkins or any other fruits or vegetables - into an easy to handle puree or mash.

The Chopper Hopper™ provides fast, simple and effective handling of waste by-products. Up to three stages of solids reduction are available for coarse, medium and fine particle size.

For additional information: Manufacturer's Website

Specifications

| Flow Rates to | 345 |

| Pressures to | 500 PSI (1155' TDH) |

| Temperatures to | 240º F |

Options & Accessories

PS220 Variable Speed Pump Controller

PumpSmart provides real-time control and protection of your pumps while also providing valuable process insight. By protecting against unplanned pump failure due to process upsets, we can keep your p...

More Info

More Info

PS30 Shaft Power Monitor

Stop Damage and Downtime Before it Occurs PumpSmart PS30 protects motor driven equipment against pump run dry, dead head, cavitation, or a closed suction valve. An alert can be as simple as a visu...

More Info

More Info